Unlocking Clarity: A Comprehensive Guide to Sheet Filtration

In various industries, achieving the desired level of purity and clarity in liquids is paramount. From pharmaceuticals and food processing to beverages and chemical manufacturing, the need for effective filtration techniques is undeniable. Among the many filtration methods available, sheet filtration stands out as a versatile and reliable option. This comprehensive guide delves into the intricacies of sheet filtration, exploring its principles, applications, advantages, and limitations.

What is Sheet Filtration?

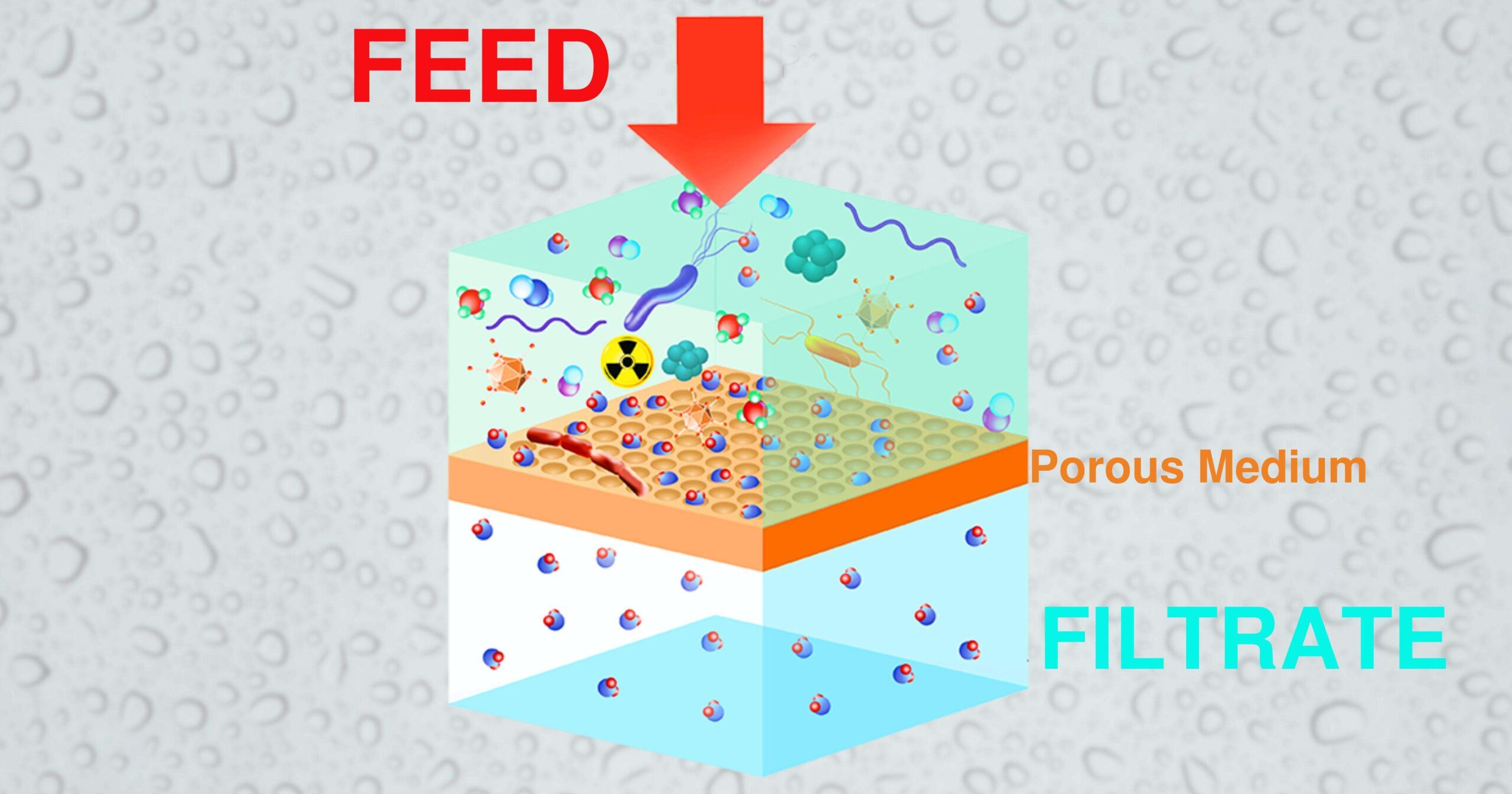

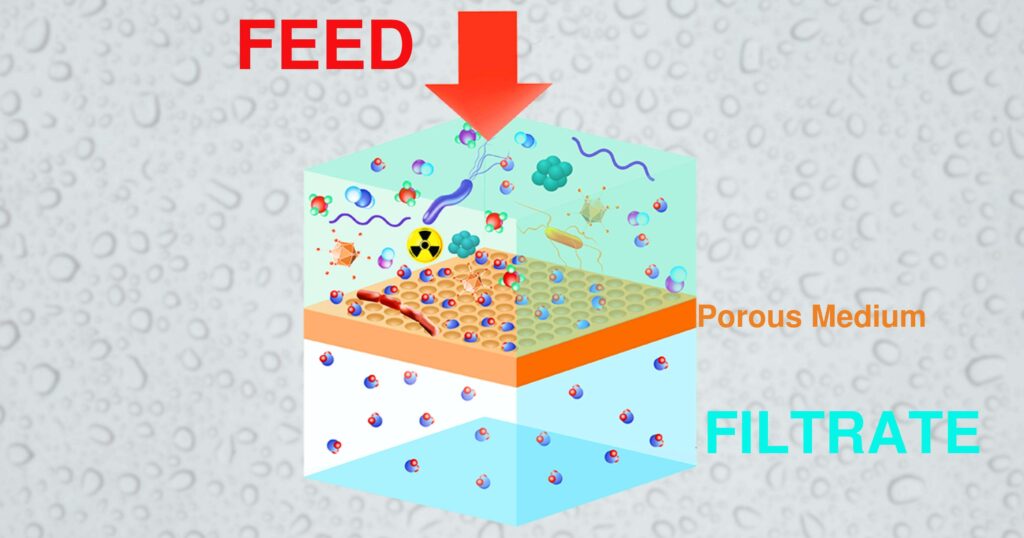

Sheet filtration, also known as depth filtration or pad filtration, is a process that uses porous sheets or pads to remove solid particles from a liquid. These sheets are typically composed of cellulose fibers, diatomaceous earth, perlite, or a combination of these materials. The sheets are designed with a complex network of pores that trap particles as the liquid passes through. Unlike surface filtration, where particles are captured on the surface of a membrane, sheet filtration captures particles within the depth of the filter sheet.

The effectiveness of sheet filtration depends on several factors, including the pore size of the filter sheet, the flow rate of the liquid, and the characteristics of the particles being removed. Different sheet grades are available with varying pore sizes, allowing for the selective removal of particles of different sizes. This makes sheet filtration a highly adaptable method suitable for a wide range of applications.

The Mechanics of Sheet Filtration

The process of sheet filtration relies on a combination of mechanical trapping and adsorption. As the liquid flows through the filter sheet, particles larger than the pore size are physically trapped within the intricate network of fibers. Smaller particles may also be captured through adsorption, where they adhere to the surface of the filter sheet material due to electrostatic forces or other chemical interactions. This dual mechanism ensures efficient removal of both large and small particles, resulting in a clarified and purified liquid.

The structure of the filter sheet is crucial to its performance. The cellulose fibers, diatomaceous earth, and perlite create a tortuous path for the liquid to flow through, increasing the likelihood of particle capture. The thickness of the sheet also plays a role, as thicker sheets provide a greater depth for particle retention. [See also: Understanding Depth Filtration Mechanisms]

Applications of Sheet Filtration

Sheet filtration is employed in a diverse array of industries, each leveraging its unique advantages. Here are some key applications:

Food and Beverage Industry

In the food and beverage industry, sheet filtration is widely used for clarifying and sterilizing liquids such as beer, wine, fruit juices, and edible oils. It effectively removes yeast, bacteria, and other particulate matter, improving the clarity, stability, and shelf life of these products. For example, wineries often use sheet filtration to remove residual yeast and sediment after fermentation, resulting in a brighter and more appealing wine. Similarly, breweries use it for final clarification before bottling or kegging.

Pharmaceutical Industry

The pharmaceutical industry relies on sheet filtration for sterilizing and clarifying injectable solutions, vaccines, and other pharmaceutical products. It ensures the removal of bacteria, pyrogens, and other contaminants that could compromise the safety and efficacy of these products. The high purity standards required in pharmaceuticals make sheet filtration an indispensable process.

Chemical Industry

In the chemical industry, sheet filtration is used for purifying a wide range of chemicals, solvents, and intermediates. It removes solid particles, precipitates, and other impurities that can affect the quality and performance of these materials. This is particularly important in the production of high-purity chemicals used in electronics, coatings, and other specialized applications. The ability of sheet filtration to handle aggressive chemicals is a significant advantage in this industry.

Cosmetics Industry

The cosmetics industry utilizes sheet filtration to ensure the clarity and purity of lotions, creams, and other cosmetic products. It removes particulate matter that could cause discoloration, sedimentation, or other undesirable effects. The use of sheet filtration contributes to the aesthetic appeal and consumer acceptance of these products. It ensures that the final product is visually appealing and free from any visible impurities.

Water Treatment

Although not as common as other filtration methods in large-scale water treatment plants, sheet filtration can be used in smaller-scale applications or as a pre-filtration step. It helps remove suspended solids and other particulate matter from water, improving its clarity and quality. This can be particularly useful in situations where a high level of purity is required, such as in the production of distilled water or ultrapure water for laboratory use. [See also: Advanced Water Filtration Technologies]

Advantages of Sheet Filtration

Sheet filtration offers several advantages over other filtration methods, making it a popular choice in many industries:

- Cost-effectiveness: Sheet filtration is generally more cost-effective than membrane filtration, especially for larger volumes of liquid. The filter sheets are relatively inexpensive and can be easily replaced.

- Ease of use: Sheet filtration systems are simple to operate and maintain, requiring minimal training. The filter sheets are easy to install and replace, and the process can be easily automated.

- Versatility: Sheet filtration can be used to filter a wide range of liquids, including those with high viscosity or high solids content. Different sheet grades are available to accommodate different particle sizes and liquid characteristics.

- Scalability: Sheet filtration can be easily scaled up or down to accommodate different production volumes. The size and number of filter sheets can be adjusted to meet the specific needs of the application.

- Depth Filtration: The depth filtration mechanism allows for a higher dirt-holding capacity compared to surface filtration. This means that sheet filtration can handle liquids with higher solids content without clogging as quickly.

Limitations of Sheet Filtration

Despite its many advantages, sheet filtration also has some limitations:

- Lower Purity: Sheet filtration generally does not achieve the same level of purity as membrane filtration. The pore sizes of filter sheets are typically larger than those of membranes, allowing some smaller particles to pass through.

- Sheet Degradation: Filter sheets can degrade over time, especially when exposed to harsh chemicals or high temperatures. This can lead to a decrease in filtration efficiency and an increase in the risk of contamination.

- Not Suitable for Sterilization: While sheet filtration can remove bacteria and other microorganisms, it is not considered a true sterilization method. Membrane filtration is typically used for sterilization applications.

- Pre-filtration May Be Needed: Liquids with very high solids content may require pre-filtration to prevent premature clogging of the filter sheets. This adds an extra step to the filtration process.

Sheet Filtration Equipment

Sheet filtration equipment typically consists of a filter housing, filter sheets, and a pump. The filter housing is designed to hold the filter sheets in place and direct the flow of liquid through them. The pump is used to force the liquid through the filter sheets at the desired flow rate. Different types of filter housings are available, depending on the application and the volume of liquid being filtered.

Plate and frame filters are a common type of equipment used for sheet filtration. These filters consist of a series of plates and frames that are stacked together to form a filter pack. The filter sheets are placed between the plates and frames, and the liquid is forced through the filter pack. Plate and frame filters are available in various sizes and configurations to accommodate different flow rates and volumes.

Lenticular filters are another type of equipment used for sheet filtration. These filters consist of a stack of lenticular modules that are sealed together to form a filter cartridge. The filter sheets are embedded within the lenticular modules, and the liquid flows through the cartridge from the outside to the inside. Lenticular filters offer a compact design and are easy to install and replace.

Selecting the Right Filter Sheet

Choosing the right filter sheet is crucial to achieving the desired level of filtration. Several factors should be considered when selecting a filter sheet, including the pore size, the material of construction, and the compatibility with the liquid being filtered.

The pore size of the filter sheet determines the size of the particles that will be removed. Finer pore sizes are used for removing smaller particles, while coarser pore sizes are used for removing larger particles. The material of construction affects the chemical resistance and temperature tolerance of the filter sheet. Cellulose-based filter sheets are suitable for a wide range of applications, while diatomaceous earth and perlite filter sheets are more resistant to high temperatures and aggressive chemicals. [See also: Choosing the Right Filtration Media]

It is also important to consider the compatibility of the filter sheet with the liquid being filtered. Some filter sheet materials may react with certain chemicals, leading to degradation or contamination. It is always recommended to consult with a filter sheet supplier to ensure that the selected filter sheet is compatible with the liquid being filtered.

Cleaning and Maintenance of Sheet Filtration Systems

Proper cleaning and maintenance are essential for ensuring the longevity and performance of sheet filtration systems. The filter sheets should be replaced regularly to prevent clogging and maintain filtration efficiency. The filter housing should also be cleaned regularly to remove any accumulated debris or contaminants.

The cleaning process typically involves flushing the filter housing with water or a cleaning solution. The filter sheets can also be cleaned by backflushing, which involves reversing the flow of liquid through the filter sheets to dislodge any trapped particles. However, backflushing is not always effective and may damage the filter sheets. In some cases, it may be necessary to replace the filter sheets altogether.

Regular inspection of the filter housing and filter sheets is also important to identify any signs of damage or wear. Damaged filter housings should be repaired or replaced to prevent leaks and contamination. Worn or damaged filter sheets should be replaced immediately to maintain filtration efficiency.

Future Trends in Sheet Filtration

The field of sheet filtration is constantly evolving, with new materials and technologies being developed to improve performance and efficiency. Some of the future trends in sheet filtration include the development of:

- Advanced Filter Sheet Materials: Researchers are exploring new materials such as nanofiber-based filter sheets that offer improved particle retention and flow rates.

- Automated Filtration Systems: Automated systems that can monitor filter performance, adjust flow rates, and replace filter sheets automatically are becoming increasingly popular.

- Integrated Filtration Systems: Integrated systems that combine sheet filtration with other filtration methods such as membrane filtration or activated carbon filtration are being developed to achieve even higher levels of purity.

- Sustainable Filtration Solutions: Environmentally friendly filter sheet materials and recycling programs are gaining traction as industries strive to reduce their environmental impact.

Conclusion

Sheet filtration remains a vital technique for achieving clarity and purity across numerous industries. Its cost-effectiveness, ease of use, and versatility make it a preferred choice for many applications. While it may not offer the same level of purity as membrane filtration, its ability to handle larger volumes and higher solids content makes it a valuable tool. By understanding the principles, applications, advantages, and limitations of sheet filtration, professionals can effectively leverage this method to meet their specific filtration needs. As technology advances, we can anticipate further innovations in sheet filtration, solidifying its role in ensuring the quality and safety of products across various sectors.