Understanding Liquid Acrylic Adhesive: Properties, Applications, and Best Practices

Liquid acrylic adhesive is a versatile bonding agent widely used across various industries. Its unique properties, such as strong adhesion, flexibility, and resistance to environmental factors, make it a preferred choice for numerous applications. This article delves into the characteristics of liquid acrylic adhesive, its diverse applications, and best practices for effective use.

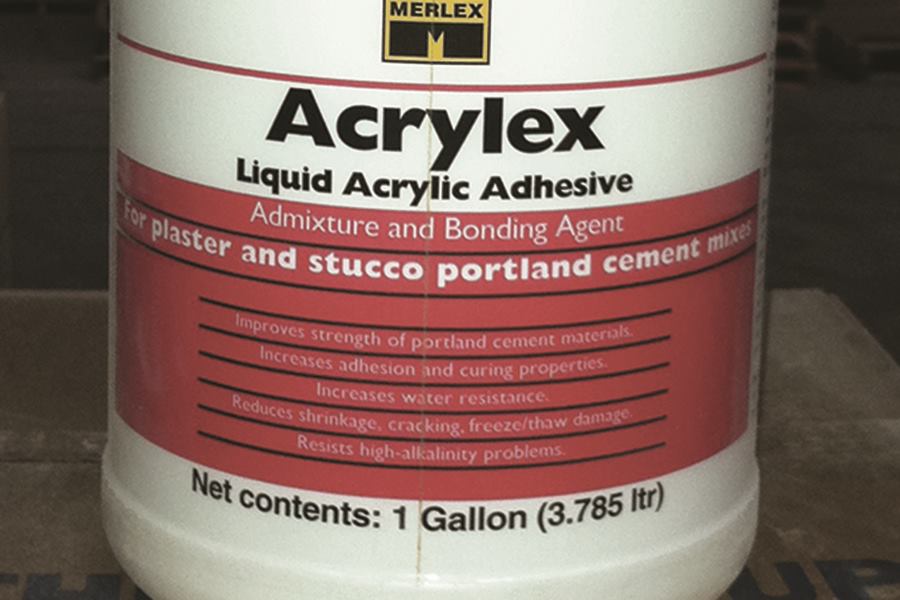

What is Liquid Acrylic Adhesive?

Liquid acrylic adhesive is a type of adhesive formulated using acrylic polymers. These polymers provide the adhesive with its key properties, including its ability to form strong bonds, resist UV radiation, and maintain flexibility over a wide temperature range. Unlike some other adhesives, liquid acrylic adhesives are available in a variety of formulations, each tailored to specific bonding requirements.

The term ‘liquid’ refers to the adhesive’s initial state, which allows for easy application and penetration into the substrates being bonded. After application, the adhesive undergoes a curing process, typically involving evaporation of a solvent or a chemical reaction, resulting in a solid, durable bond.

Key Properties of Liquid Acrylic Adhesives

Several properties make liquid acrylic adhesive a standout choice for many applications:

- Strong Adhesion: Acrylic adhesives exhibit excellent adhesion to a variety of substrates, including plastics, metals, glass, and composites.

- Flexibility: They maintain flexibility even after curing, allowing them to withstand vibrations, impacts, and thermal expansion/contraction without cracking or losing bond strength.

- UV Resistance: Acrylic polymers are inherently resistant to ultraviolet (UV) radiation, making these adhesives suitable for outdoor applications where exposure to sunlight is a concern.

- Water Resistance: Many formulations of liquid acrylic adhesive offer good resistance to water and humidity, making them suitable for applications in damp or wet environments.

- Chemical Resistance: Depending on the specific formulation, liquid acrylic adhesives can offer resistance to a range of chemicals, including oils, solvents, and acids.

- Temperature Resistance: They can maintain their bond strength over a wide temperature range, from low temperatures to elevated temperatures, depending on the formulation.

- Clarity: Some formulations are optically clear, making them suitable for applications where aesthetics are important, such as bonding transparent materials.

Applications of Liquid Acrylic Adhesive

The versatility of liquid acrylic adhesive makes it suitable for a wide range of applications across various industries:

Automotive Industry

In the automotive industry, liquid acrylic adhesives are used for bonding various components, including interior trim, exterior panels, and structural elements. Their ability to withstand vibrations, temperature changes, and exposure to chemicals makes them ideal for automotive applications. For example, they are commonly used to bond plastic emblems and trim pieces to metal surfaces.

Electronics Industry

The electronics industry utilizes liquid acrylic adhesive for bonding electronic components, securing wires, and encapsulating sensitive parts. Their electrical insulation properties and resistance to moisture make them suitable for protecting electronic circuits from environmental damage. They’re also used to bond LCD screens to housings.

Construction Industry

In construction, liquid acrylic adhesives are used for bonding building materials such as wood, concrete, and metal. Their strong adhesion and resistance to environmental factors make them suitable for both interior and exterior applications. Applications include bonding insulation materials, attaching decorative elements, and sealing joints.

Aerospace Industry

The aerospace industry relies on high-performance adhesives, and liquid acrylic adhesive formulations are often used in non-structural applications. Their ability to withstand extreme temperatures, vibrations, and exposure to chemicals makes them suitable for bonding interior panels, securing wires, and sealing joints. Stringent testing and quality control are critical in this industry.

Marine Industry

The marine industry requires adhesives that can withstand exposure to saltwater, UV radiation, and extreme weather conditions. Liquid acrylic adhesive formulations designed for marine applications offer excellent resistance to these factors, making them suitable for bonding boat components, sealing joints, and repairing fiberglass structures.

Signage and Display Industry

The signage and display industry utilizes liquid acrylic adhesive for bonding various materials, including acrylic sheets, metal frames, and plastic components. Their clarity and UV resistance make them ideal for creating durable and visually appealing signs and displays. They are used for bonding letters to signs and securing display panels to frames.

Types of Liquid Acrylic Adhesives

Liquid acrylic adhesives come in several types, each with its own unique characteristics and applications:

- Solvent-Based Acrylic Adhesives: These adhesives use a solvent as a carrier for the acrylic polymer. They offer good adhesion and are suitable for a wide range of materials. However, they may release volatile organic compounds (VOCs) during curing.

- Water-Based Acrylic Adhesives: These adhesives use water as a carrier for the acrylic polymer. They are environmentally friendly and have low VOC emissions. However, they may have slower curing times compared to solvent-based adhesives.

- Reactive Acrylic Adhesives: These adhesives cure through a chemical reaction, typically involving a catalyst or initiator. They offer fast curing times and strong bonds.

- UV-Curable Acrylic Adhesives: These adhesives cure when exposed to ultraviolet (UV) light. They offer very fast curing times and are suitable for applications where rapid bonding is required.

Best Practices for Using Liquid Acrylic Adhesive

To achieve optimal results when using liquid acrylic adhesive, it is important to follow best practices for surface preparation, application, and curing:

Surface Preparation

Proper surface preparation is crucial for achieving a strong and durable bond. Surfaces should be clean, dry, and free from contaminants such as dirt, oil, and grease. Use appropriate cleaning agents and methods for the specific materials being bonded. Abrading the surface slightly can also improve adhesion by increasing the surface area available for bonding.

Application

Apply the liquid acrylic adhesive evenly to one or both surfaces being bonded. Use the appropriate application method for the specific adhesive and application requirements. This may involve using a brush, roller, spray gun, or dispensing equipment. Ensure that the adhesive is applied in a thin, uniform layer to avoid excessive squeeze-out and ensure proper curing.

Curing

Allow the adhesive to cure according to the manufacturer’s instructions. Curing times can vary depending on the type of adhesive, temperature, and humidity. Ensure that the bonded assembly is properly supported during the curing process to prevent movement or distortion. For UV-curable adhesives, use the appropriate UV light source and exposure time to ensure complete curing.

Safety Precautions

Always follow safety precautions when working with liquid acrylic adhesive. Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators, to protect against skin contact, eye irritation, and inhalation of vapors. Work in a well-ventilated area to minimize exposure to VOCs. Dispose of waste materials properly according to local regulations.

Troubleshooting Common Issues

Even when following best practices, you may encounter issues when using liquid acrylic adhesive. Here are some common problems and their solutions:

- Poor Adhesion: This may be due to inadequate surface preparation, improper adhesive selection, or insufficient curing. Ensure that surfaces are properly cleaned and prepared, select an adhesive that is compatible with the materials being bonded, and allow sufficient curing time.

- Bubbles or Voids: These may occur if the adhesive is applied too thickly or if air is trapped during application. Apply the adhesive in a thin, uniform layer and use techniques to minimize air entrapment, such as rolling or brushing the adhesive.

- Premature Curing: This may occur if the adhesive is exposed to excessive heat or UV light during storage or application. Store the adhesive in a cool, dark place and avoid exposure to direct sunlight or UV light.

- Weak Bond Strength: This may be due to improper adhesive selection, inadequate surface preparation, or insufficient curing. Select an adhesive that is designed for the specific application requirements, ensure that surfaces are properly prepared, and allow sufficient curing time.

The Future of Liquid Acrylic Adhesives

The market for liquid acrylic adhesives is expected to continue to grow in the coming years, driven by increasing demand from various industries, including automotive, electronics, construction, and aerospace. Ongoing research and development efforts are focused on improving the performance, durability, and environmental friendliness of these adhesives. [See also: Innovative Adhesive Technologies] Future trends may include the development of bio-based acrylic adhesives, adhesives with enhanced temperature resistance, and adhesives with improved adhesion to difficult-to-bond materials.

Conclusion

Liquid acrylic adhesive is a versatile and reliable bonding agent with a wide range of applications. Its unique properties, such as strong adhesion, flexibility, UV resistance, and water resistance, make it a preferred choice for numerous industries. By understanding the characteristics of liquid acrylic adhesive, following best practices for application and curing, and addressing common issues, you can achieve optimal results and create durable, long-lasting bonds. As technology advances, expect even more innovative and specialized liquid acrylic adhesive formulations to emerge, further expanding their application possibilities.