Unlocking the Potential of Acrylic Circles: A Comprehensive Guide

In the world of design, fabrication, and art, few materials offer the versatility and aesthetic appeal of acrylic. Among the various forms acrylic takes, acrylic circles stand out for their unique combination of functionality and visual charm. From industrial applications to artistic endeavors, acrylic circles are finding their place in an ever-expanding range of projects. This comprehensive guide explores the diverse uses, benefits, and considerations involved in working with acrylic circles.

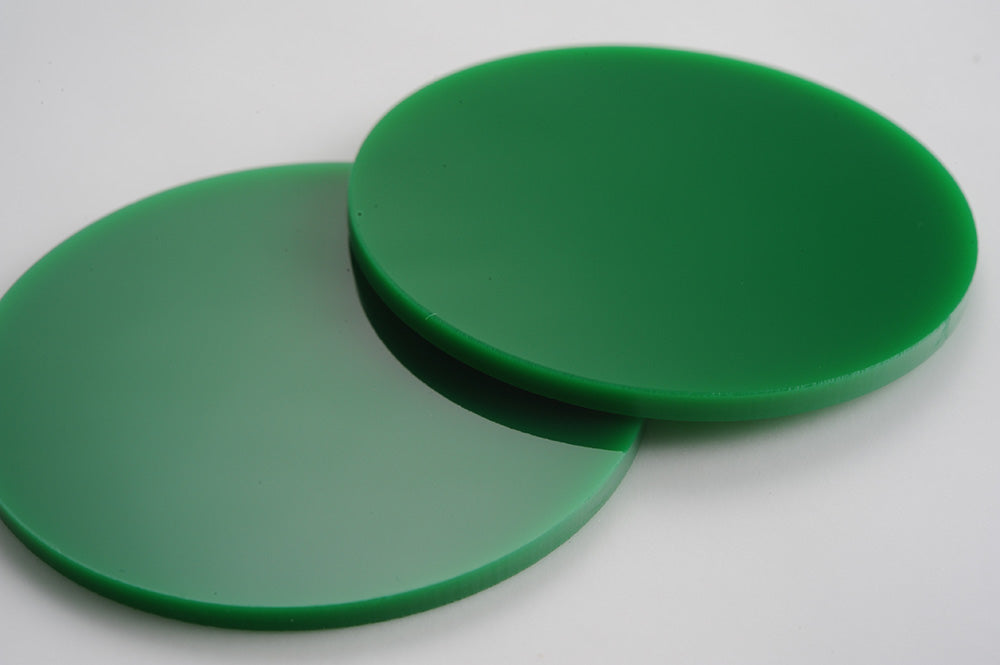

What are Acrylic Circles?

Acrylic circles are precisely cut circular shapes made from acrylic, a synthetic polymer known for its transparency, durability, and ease of manipulation. Often referred to as Plexiglas or Lucite (though these are brand names), acrylic boasts several advantages over glass, including being lighter, more shatter-resistant, and easier to cut and shape. These qualities make acrylic circles a popular choice for various applications.

The Benefits of Using Acrylic Circles

- Transparency: Acrylic offers exceptional optical clarity, often surpassing that of glass. This makes acrylic circles ideal for applications where visibility is crucial, such as display cases or lenses.

- Durability: Acrylic is significantly more impact-resistant than glass, reducing the risk of breakage and making it a safer option, especially in high-traffic areas.

- Lightweight: Compared to glass, acrylic is much lighter, making it easier to handle, transport, and install. This is particularly beneficial for larger acrylic circles.

- Versatility: Acrylic can be easily cut, drilled, shaped, and polished, allowing for a wide range of design possibilities. Acrylic circles can be customized to meet specific project requirements.

- Weather Resistance: Acrylic is resistant to the effects of UV radiation and moisture, making it suitable for both indoor and outdoor applications.

- Chemical Resistance: Acrylic exhibits good resistance to many chemicals, making it appropriate for use in environments where exposure to certain substances is likely.

Applications of Acrylic Circles

The versatility of acrylic circles lends itself to a multitude of applications across various industries. Here are some notable examples:

Architectural and Design Elements

Acrylic circles are frequently used in architectural design as windows, skylights, or decorative panels. Their ability to transmit light while providing structural support makes them an attractive alternative to traditional glass. Interior designers also incorporate acrylic circles into furniture, lighting fixtures, and wall art to add a modern and sophisticated touch. [See also: Modern Interior Design Trends]

Retail Displays and Signage

In the retail sector, acrylic circles are employed to create eye-catching displays for products and promotional materials. Their transparency allows for clear visibility of the items on display, while their durability ensures that the displays can withstand the rigors of a retail environment. They are also used for signage, providing a sleek and professional look. Backlit acrylic circles can create particularly striking signage.

Industrial Applications

Acrylic circles find applications in various industrial settings. They can be used as sight glasses in machinery, providing a clear view of internal processes. Their chemical resistance makes them suitable for use in laboratory equipment and chemical processing plants. Furthermore, they are used as protective shields in manufacturing environments. The precision with which acrylic circles can be manufactured is critical in these applications.

Artistic and Creative Projects

Artists and craft enthusiasts frequently utilize acrylic circles in their projects. They can be painted, engraved, or embellished to create unique works of art. Their smooth surface makes them ideal for painting and drawing, while their transparency allows for interesting layering effects. Acrylic circles can also be incorporated into sculptures and mixed-media art pieces. [See also: DIY Acrylic Painting Techniques]

Aquariums and Marine Applications

Due to their strength and clarity, acrylic circles are sometimes used in the construction of small aquariums or as viewing ports in larger tanks. While not as common as rectangular acrylic panels for large aquariums, acrylic circles can provide a unique and aesthetically pleasing design element. Their resistance to saltwater corrosion is also a significant advantage.

Protective Covers and Shields

Acrylic circles can be used as protective covers for sensitive equipment or instruments. Their transparency allows for easy monitoring of the covered item, while their durability provides protection from dust, scratches, and other environmental factors. They are commonly used in museums to protect valuable artifacts. The ability to customize the thickness and diameter of the acrylic circles makes them suitable for a wide range of protective applications.

Factors to Consider When Choosing Acrylic Circles

When selecting acrylic circles for a specific project, several factors should be taken into consideration:

Thickness

The thickness of the acrylic sheet will determine its strength and rigidity. Thicker acrylic circles are more resistant to bending and breakage, making them suitable for applications where structural integrity is important. The appropriate thickness will depend on the size of the circle and the load it will bear.

Diameter

The diameter of the acrylic circle will depend on the specific dimensions required for the project. It is important to accurately measure the space where the circle will be installed to ensure a proper fit. Acrylic circles can be custom-cut to virtually any diameter.

Color and Finish

Acrylic circles are available in a wide range of colors, from clear to opaque. The choice of color will depend on the desired aesthetic effect. Different finishes, such as glossy or matte, can also be chosen to further customize the appearance of the acrylic circle. Consider the lighting conditions and the surrounding environment when selecting the color and finish.

Quality and Grade

The quality of the acrylic material will affect its clarity, durability, and overall performance. It is important to choose acrylic circles made from high-quality, virgin acrylic resin. This will ensure that the circle is free from imperfections and will maintain its clarity over time. Ask about the manufacturer’s quality control processes.

Manufacturing Process

The manufacturing process used to create the acrylic circles can also affect their quality. Laser cutting and CNC routing are common methods that provide precise and clean cuts. Ensure that the manufacturing process is appropriate for the intended application and that the edges are properly finished.

Working with Acrylic Circles: Tips and Techniques

Working with acrylic circles requires some specialized techniques to avoid damaging the material. Here are some helpful tips:

Cutting

Acrylic circles can be cut using a variety of tools, including laser cutters, CNC routers, and specialized acrylic saws. When cutting acrylic, it is important to use a sharp blade and to avoid overheating the material. Applying a coolant can help to prevent melting and chipping. [See also: Laser Cutting Acrylic Guide]

Drilling

Drilling holes in acrylic circles requires the use of specialized acrylic drill bits. These bits are designed to prevent cracking and chipping. It is important to drill slowly and to apply a coolant to prevent overheating. Back up the acrylic with a piece of wood to prevent tear-out on the exit side of the hole.

Polishing

The edges of acrylic circles can be polished to a high gloss using a buffing wheel and acrylic polishing compounds. Polishing removes any imperfections and creates a smooth, transparent edge. Start with a coarse compound and gradually move to finer compounds to achieve the desired finish.

Cleaning

Acrylic circles should be cleaned with a soft cloth and a mild detergent. Avoid using abrasive cleaners or solvents, as these can scratch or damage the surface. A dedicated acrylic cleaner is recommended for optimal results. Regular cleaning will help to maintain the clarity and appearance of the acrylic.

Conclusion

Acrylic circles offer a unique combination of aesthetic appeal, durability, and versatility, making them a valuable material for a wide range of applications. From architectural design to artistic creations, acrylic circles provide a modern and sophisticated touch. By understanding the benefits, considerations, and techniques involved in working with acrylic circles, designers, fabricators, and artists can unlock their full potential and create innovative and impactful projects. The continued development of acrylic technology promises even more exciting applications for acrylic circles in the future. Choosing the right supplier and understanding the specific needs of your project are key to successfully incorporating acrylic circles into your work.